Please contact us for specific information on these projects and many others.

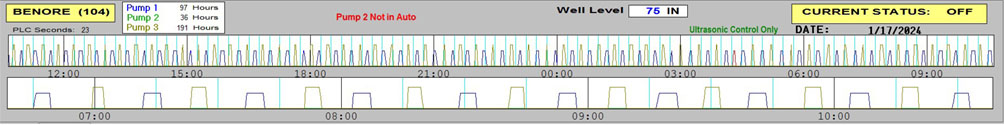

Benore Sanitary Pump Station was rebuilt & upgraded in late 2023. This included all electrical, pump controls, & telemetry. A new ControLogix PLC was designed and installed to drive improvements in real time monitoring status, automated pump controls, & data collection. New SCADA for this small sanitary pump station included:

It is also of note that these improvements set a standard going forward for any new small form factor sanitary pump stations OR for any improvements to existing small sanitary stations. This includes storm water stations as well.

Converted 11 rain gauges throughout the 84 square miles of the Toledo area to direct reporting to a co-located programmable logic controller (PLC). This allowed us to remove the faulty digital to analog back to digital electronic instruments that were un-reliable. This project includes the addition of two new rain gauges & the re-location of two others to more suitable sites. A centrally located weather station was also upgraded to instruments that report directly to a co-located PLC. Further details of this work include PLC programming, SCADA programming & data acquisition configuration. Rain & weather instrument specifications were modeled on those devices used by the National Weather Service (NWS). Data communications were improved to allow direct data access from all eleven remote sites back to the main treatment facility

The primary focus of this project was to improve reliablility and to lay the groundwork for rain gauge data recording & archiving in conjunction with the verification processes of several Toledo Waterways Initiative (TWI) installations. Ultimately, reliable rain gauge data would be avaiable for various modeling scenarios and project performance certification.

This work encompassed all aspects of the rain data collection process, from the individual tipping bucket style gauges in the field thru the digital connection to the PLC, on to the SCADA software portion that made real time rain data available, to the final database process that archived rain data and allowed SQL query access for reporting & modeling.

In January of 2017, an important milestone was reached. The Division’s last AT&T provided analog leased-line circuit was put to rest. This event concluded a project that primarily dealt with the elimination of all analog type circuits and their associated equipment. Their replacement was either 900Mhz / 2.4Ghz wireless Ethernet radio telemetry or 1.54Mbps T1 circuits from AT&T under pricing set forth in the State of Ohio contract. Immediately following this, attention was focused on another project to convert the 13 remaining T1 circuits to AT&T's new Switched Ethernet service. By 2021, all of these 1.54Mbps circuits had been replaced with 2.0Mbps switched Ethernet. With a main router upgrade in 2022, all AT&T hosted services had been upgraded and integrated into the Collection system SCADA at the City of Toledo, Divsion of Water Recalamtion

There were numerous motivations for these projects. Both wireless Ethernet and switched Ethernet circuits provide improved data throughput and enhanced SCADA capabilities from our system of over 80 remote pump stations, CSO Regulators, interceptor sewer monitors, and rain gauges. Additionally, this work was encouraged by the City’s Accounting Division, who were forced to process many significant rate increases from AT&T on a quarterly basis. The AT&T monthly charge for a typical pump station serviced by an analog leased-line was in excess of $1100.00. Later, as T1 circuits were phased out, the Switched Ethernet service from AT&T resulted in similar savings based on previous negotiated pricing set forth in the State of Ohio contract.

As stated, these projects eliminated all obsolete and antiquated analog leased-lines. It also reduced our AT&T footprint to just 13 switched Ethernet circuits. Single mode fiber optics, wireless Ethernet and proprietary radio telemetry now covered a significant portion of the Telemetry system. This resulted in a significant cost reduction and far cry from the 82 analog circuits that existed at the turn of the millenium (Year 2000). Furthermore and most important, yearly expenditures with AT&T were reduced down to a figure of about $42,000 This compares to over $250,000 that was previously being set aside in this City Division’s budget for circuits & telemetering.

Developed PLC code to record sewer overflow notice, duration, rate (in MGD / GPS), volume and totalized volume. When a direct connection to a PLC did not exist, code was developed within the SCADA software to accomplish this task.

This work encompassed all aspects of the combined sewer overflow data collection process, from the individual ultrasonic level systems in the respective CSO weir chamber to both digital & analog connections to a co-located PLC or telemetry system, on to the SCADA software portion that made real time scaleable CSO data available, to the final database process that archived CSO data and allowed SQL query access to reporting & modeling.

This work too, was elevated in importance to provide reliable recording & modeling data for the TWI verification process. This includes individaul projects related to constructed basins, tunnels, & holding tanks, AND the final 1-year study required by the US EPA Consent Decree.

When upgrade and/or replacment costs became too expensive, it was decied to replace this indication system with a equal or better replication within our SCADA software applcation dedicated to the 4160 VAC electrical grid. The original mimic board system, consisting of simple light bulbs driven by PLC outputs was limited in its scope. By converting to a software based representation, other readings related to the electrical grid could easily be displyed. These include analog readings such as real time electrical demand in KW, current readings from key electrical processes, alarm banners & and more detailed indications. By converting to a software based system, cost savings were significant (tens of thousands).

Led a concerted effort to replace older / deprecated DC driven variable frequency drives (VFDs) with AC based PowerFlex drives from Allen-Bradley in a digested sludge process. This work included the supervision of demolition & installation, direct installation, drive configuration with Allen Bradley's Connected Components Workbench (CCW) software. Further work included any & all PLC related tasks, such as PLC wiring and PLC code changes to better accomodate the new AC VFD drives. This work continued on into the related SCADA application, where several enhancements wre included. Several drives were upgraded / replaced under this project.

Read the Report (Adobe PDF Format)

This document was compiled to inform and educate Plant Operators & Operations Supervisors on the wide range of changes, upgrades, & repairs made by

the Engineering controls and SCADA section here at the Toledo Water Reclamation Plant. Going forward, the primary focus of this content is based on the SCADA screens that are located

in the SDB/SH Operator office on the 5th floor of the Solids Dewatering Building and the local SCADA screens associated with each Belt Filter Press that was re-built mechanically in 2021-22.

These changes & upgrades began with the Solids Dewatering Building 3rd floor polymer delivery system, primarily with the automated filling of the belt filter press day tank.

These upgrades and improvements continued thru 2023, with a focus on completing the automation of sludge & polymer to Belt Filter Presses 2, 4, & 6.